DESIGN-TO-DELIVERY FOR HOME & LIVING BRANDS

Sampling, production, QC, consolidation and delivery, all managed by one partner

Design to Delivery, We Bring Your Products to Life

At scale. With speed.And full transparency.

We help home and living brands develop, manufacture, and deliver products faster through a vertically integrated model—combining design, factory partnerships, quality control, and logistics. Your products move from concept to container with consistency, reliability, and clear communication at every step.

20+ Years of Industry Experience

Dedicated Design & Teams across India and UK

Certified & Audited Factory Network

What We

Deliver

01

Product Development

Fast development from moodboard to CADs to prototype. Trend mapping, material selection, and multi-category sampling.

02

Manufacturing at Scale

Reliable, audited factories across wood, metal, upholstery, rugs, and textiles with consistent lead times and predictable costing.

03

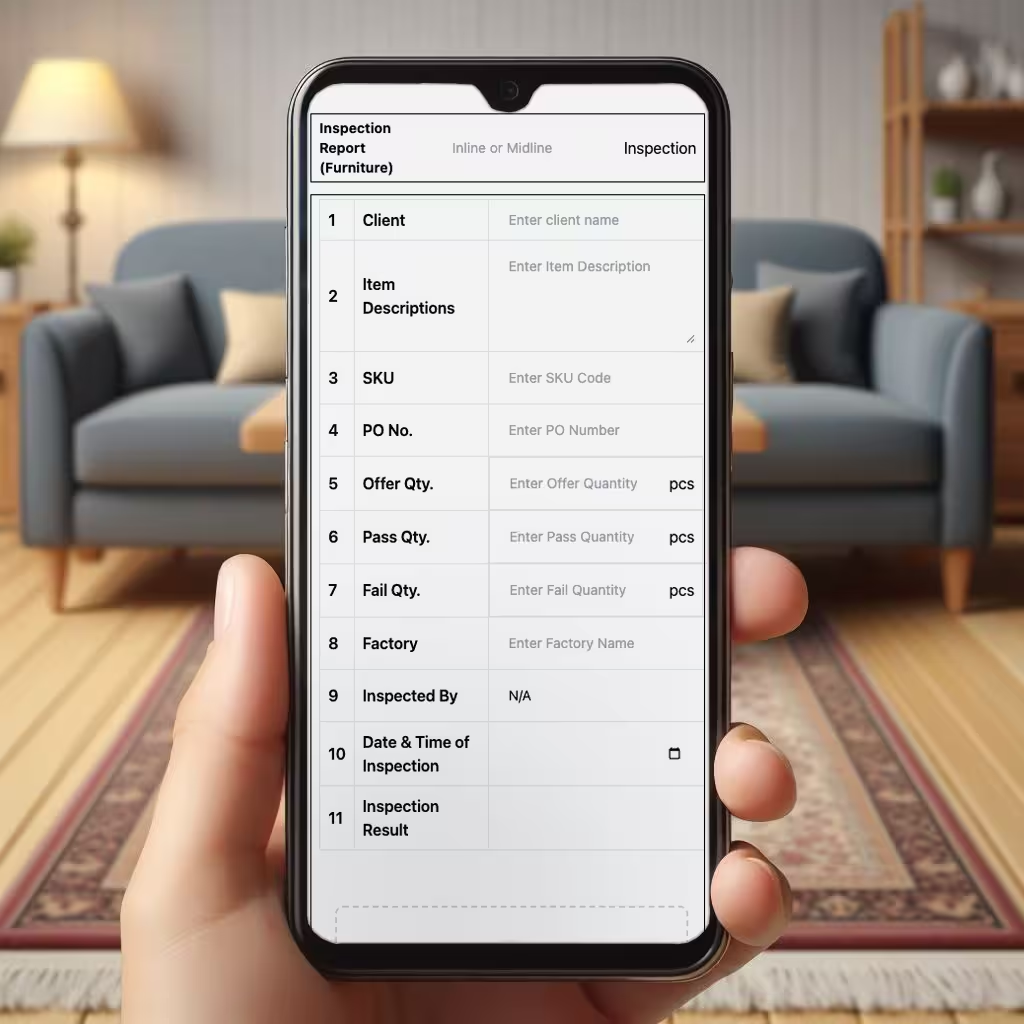

Quality Control

In-line QC, finish checks, packaging checks, and final inspections with real-time reports from our on-ground QC team.

Core Categories

Tap any category to expand

Core Categories

Accent chairs, office seating, loungers and upholstered pieces, crafted in skilled multi-category factories across Vietnam, with comfort and character at the forefront. Every style is chosen for its premium fabric, thoughtful detailing and the ease with which it fits a preferred look and feel.

Accent chairs, office seating, loungers and upholstered pieces, crafted in skilled multi-category factories across Vietnam, with comfort and character at the forefront. Every style is chosen for its premium fabric, thoughtful detailing and the ease with which it fits a preferred look and feel.